Why Systems of Systems?

In a world rapidly transforming by technology, the future of industries is being reshaped by the seamless integration of Systems of Systems and the adoption of Industry 4.0 principles.

Picture autonomous mobile robots (AMRs), machines, sensors, and other devices collaborating harmoniously to propel your operations forward. These interconnected systems communicate in real-time, sharing data and insights, and unlocking unprecedented levels of resilience and efficiency.

Read MoreAvdaga’s Approach (How):

Systems of Systems are inherently complex, especially as they expand. Managing these complexities is challenging due to the many dependencies involved, often leading to unexpected complications and increased costs.

Even with effective stakeholder alignment, the sheer number of interconnected components obscures the development scope, making it difficult to reliably estimate effort and costs

Read MoreAvdaga’s Approach: Ensuring Engagement & Reducing Complexity

We recognize that the key to successful Systems of Systems implementation lies in people. That's why we prioritize stakeholder engagement from the very start, collaborating closely with your team and Subject Matter Experts (SMEs) to develop a shared understanding of your long-term vision and objectives.

This collective knowledge is then compiled into the preliminary System Architecture. As the system evolves, the architecture acts as a roadmap for growth, ensuring seamless integration of new technologies and components while preserving existing functionality

Read MoreModular Architecture

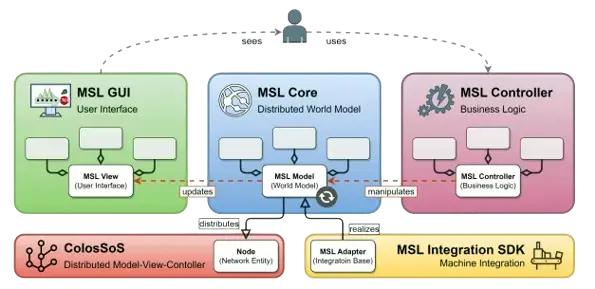

The architecture enables system developers to treat the SmartLine as one entity (one codebase), which reduces overhead and ensures cohesion. The software is only split up during deployment, ensuring each device receives the necessary software. Our ColosSoS data modeling and distribution framework/engine is the foundation that enables such modular architecture.

Benefits of the integrated systems of systems include But are not limited to

-

Higher Quality & Better Customer Experience

It is easier to operate one integrated system than numerous individual subsystems separately. It requires fewer operators, enables faster (configuration) changeovers, automated tracking, tracing and reporting, and more straightforward problem-solving.

-

Improved Efficiency & Productivity

Increased situational awareness and (semi-)automated decision-making will reduce downtime, and resource, material, and product waste.

-

Flexibility And Agility

It is easier to install and configure new machine lines in different facilities, introduce new machine types, and deploy updates.

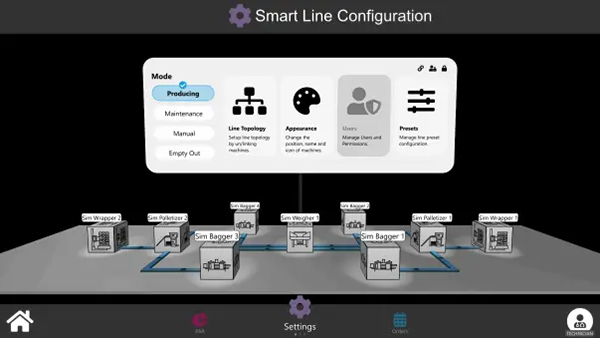

SmartLine Configuration [WIP]

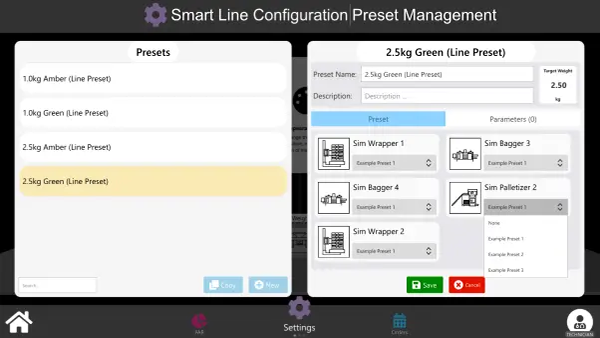

Line Recipe / Preset configuration is done by choosing a recipe for each machine.

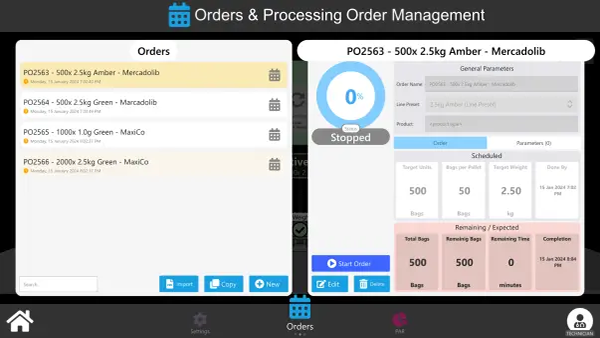

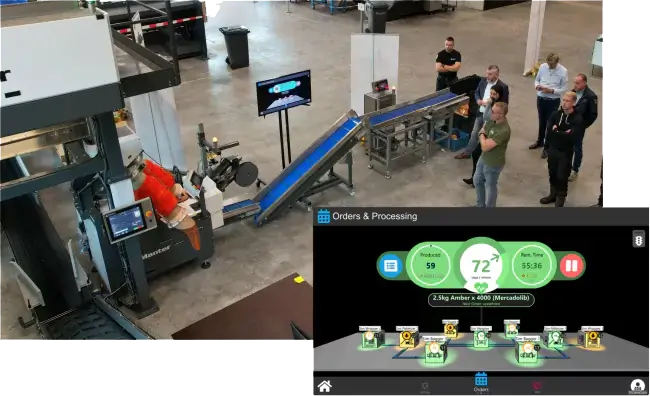

Management Order Processing &Orders

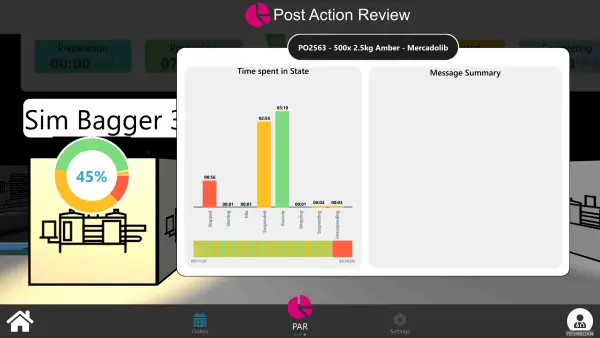

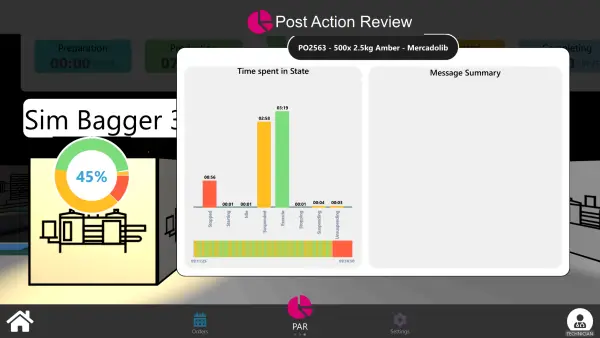

Operational Intelligence: Post-Action Review

Operational Intelligence: Post-Action Review

Why Why Choose Us

Secure

All computers and mobile devices undergo protection measures to safeguard your company's sensitive data. Regular updates are implemented and enforced, while proactive system monitoring notifies us of any potential issues before they can lead to downtime.

Connect

Cisco Meraki Networking and it’s cloud based management ensures a reliable connection to your business resources, both internal and in in the cloud.

Empower

A workstation and network fortified with security measures ensure that your employees can effectively carry out their critical tasks. They can operate within a system that is both supported and safeguarded

Technology Portfolio SmartLine

The production industry faces a growing set of challenges: staff shortages, a lack of available experts, different expectations of younger workforce generations, and the unavailability of off-the-shelf solutions.

SmartLine Integration

The SmartLine system integrates various machines, giving the operator centralized control while informing the operations manager of disruptions. It is designed to fulfill the following objectives:

The unified User Interface simplifies line operation & order processing and provides a better user experience for operators, reducing start-up and change-over times;

Mobile notifications & remote monitoring keep operators and facility managers informed of machine and line stoppages, reducing unnoticed production downtime;

Data collection and visualization empower facility managers to benchmark the performance of a line to set better expectations on production capacity and improve order scheduling;

The SmartLine Adapter Development Kit simplifies integration, reducing the time required to add machines to the SmartLine, and enabling prompt expansion of SmartLine interoperability;

Maintenance forecasts prevent unexpected machine failures and enable timely delivery of replacements, reducing production downtime; and,

The modular architecture combined with continuous integration on representative hardware reduces the time between the development of features and the pushing of software updates to customers;